Footwear Safety Standards: The Ultimate Guide To EN345 [Infographic]

We all know and understand the importance of having the right safety footwear in the workplace. Especially those of us that have suffered a foot injury that could be avoided if the proper safety footwear was used. About a quarter of all disability applications in the world are due to foot injuries. That is why all safety footwear has to meet the minimum safety standard set out by the International Organization for Standardization (ISO).

We have put together an ultimate guide to the footwear safety standards - EN ISO 345.

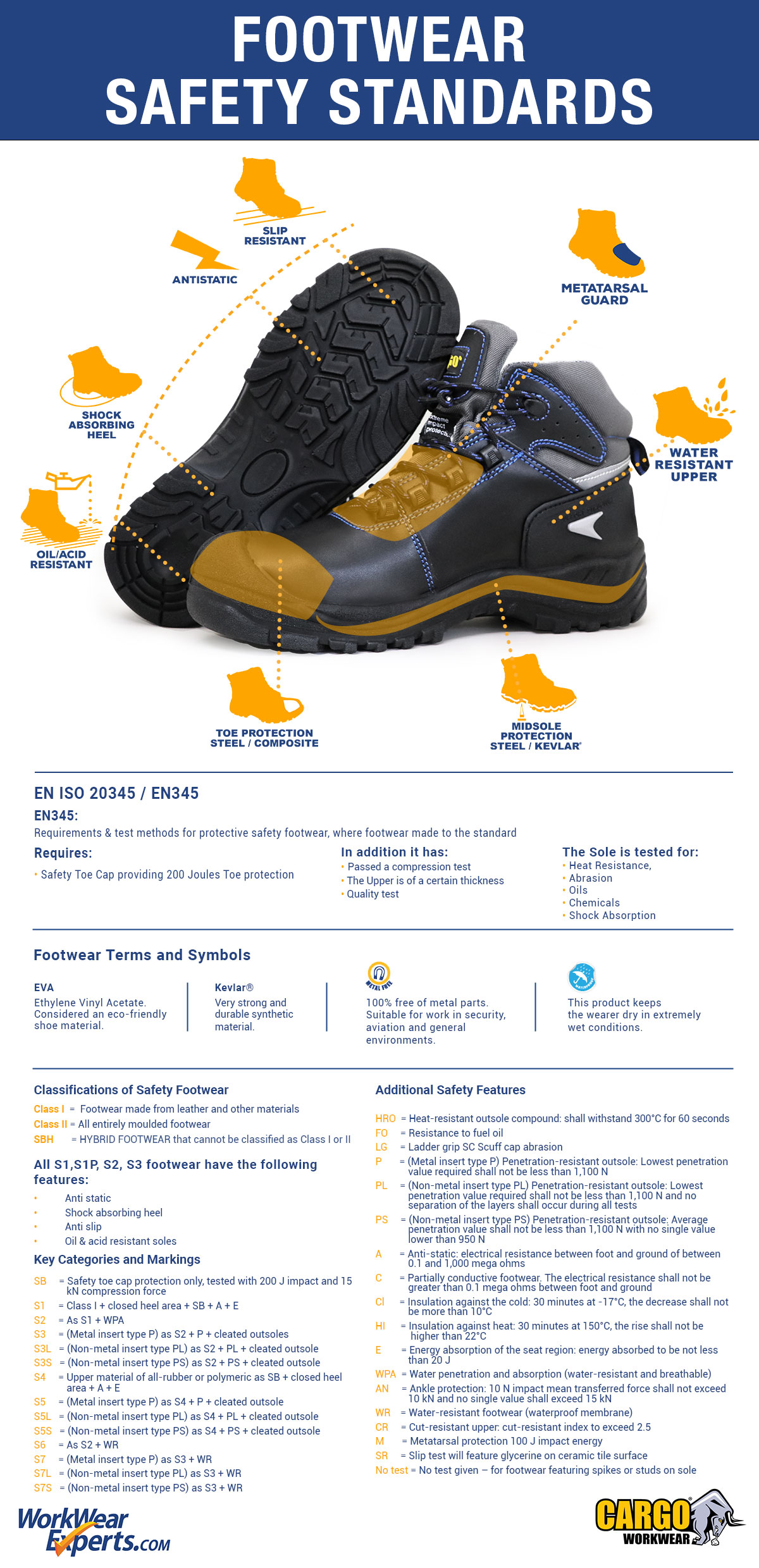

What is EN ISO 20345 / EN345?

EN ISO 20345:2022 is a safety standard that defines the specifications for safety footwear used across various workplaces. It sets the minimum requirements for footwear, including mechanical risks, slip resistance, thermal properties, and ergonomic design. The standard ensures that all certified footwear provides the necessary protection to prevent foot injuries caused by heavy objects, sharp materials, and environmental conditions.

Classifications of Safety Footwear in EN ISO 20345:2022

The EN ISO 20345:2022 standard classifies safety footwear into different categories based on their materials and specific protective features. The classifications include:

- Class I: Footwear made from leather and other materials (non-moulded).

- Class II: Entirely moulded footwear (typically rubber or polymeric).

- SBH: Hybrid footwear that cannot be classified as Class I or II, combining features of both.

Each class is further divided into categories that specify the level of protection and the specific requirements they meet.

Key Categories and Markings

The EN ISO 20345:2022 standard uses a series of markings to indicate the specific safety features and protection levels provided by the footwear:

- SB: Safety Basic, featuring a safety toe cap that protects against impacts of 200 Joules and compression up to 15 kN.

- S1: Includes SB features plus anti-static properties (A), energy absorption in the heel area (E), and a closed heel design.

- S2: Builds on S1 by adding water penetration and absorption resistance (WPA).

- S3: Expands S2 by adding penetration-resistant properties with a metal insert (P) and a cleated outsole for better grip.

- S3L: Similar to S3, but with a non-metallic penetration-resistant insert (PL).

- S3S: Similar to S3, but with a non-metallic insert (PS) that meets specific testing standards.

- S4: Comprises footwear made entirely of polymer or rubber, offering the features of SB, anti-static properties, energy absorption in the heel, and a closed heel.

- S5: Like S4, but with the addition of a penetration-resistant midsole using a metal insert (P) and a cleated outsole.

- S5L: As S5 but with a non-metallic penetration-resistant insert (PL).

- S5S: As S5 but with a non-metallic insert (PS).

- S6: Includes S2 features along with water-resistant properties (WR).

- S7: Expands on S3 with added water resistance (WR).

Additional Safety Features in EN ISO 20345:2022

The standard also includes optional features for enhanced protection against specific risks:

- HRO (Heat-Resistant Outsole): The outsole must withstand temperatures of up to 300°C for 60 seconds without damage.

- FO (Fuel Oil Resistance): The outsole resists degradation upon exposure to fuel oils.

- LG (Ladder Grip): Specially designed soles to provide a secure grip on ladder rungs.

- P/PL/PS: Penetration-resistant midsoles protect against sharp objects. Metal inserts (P) and non-metal inserts (PL, PS) must withstand forces of 1,100 N.

- A (Anti-static): Prevents the build-up of static electricity, reducing the risk of electrical discharges in sensitive environments.

- C (Partially Conductive): Ensures electrical resistance is not greater than 0.1 mega ohms, useful for specific electrical work environments.

- Cl (Cold Insulation): Protects against cold temperatures, with a decrease of no more than 10°C when exposed to -17°C for 30 minutes.

- HI (Heat Insulation): Protects against heat, with a temperature rise of no more than 22°C after 30 minutes at 150°C.

- E (Energy Absorption): The heel area must absorb energy up to 20 Joules, reducing the impact during walking or jumping.

- AN (Ankle Protection): Ensures impact forces on the ankle are below 10 kN for added protection.

- CR (Cut Resistance): The upper part of the shoe must achieve a cut resistance index above 2.5.

- M (Metatarsal Protection): Protects the upper foot from impacts with energy up to 100 Joules.

- WR (Water-Resistant): Ensures water does not penetrate the footwear, providing a waterproof solution for wet environments.

Slip Resistance in EN ISO 20345:2022

Slip resistance is now a mandatory requirement for all safety footwear under EN ISO 20345:2022. The slip resistance test involves using glycerine on ceramic tile surfaces to ensure the footwear can provide adequate grip in slippery conditions. This change aims to reduce slips, trips, and falls in the workplace, making footwear safer for diverse environments.

Comprehensive Testing Methods

EN ISO 20345:2022 sets rigorous testing standards to ensure the footwear meets all the safety requirements:

- Impact and Compression Testing: Ensures the toe cap can withstand 200 Joules of impact and 15 kN compression force.

- Penetration Resistance: Tests the ability of the outsole to resist penetration by sharp objects, using both metal and non-metal inserts.

- Water Resistance: Verifies that water cannot penetrate the footwear under controlled conditions.

- Thermal and Electrical Testing: Ensures protection against extreme temperatures and electrical hazards.

- Slip Resistance Testing: Evaluates grip performance on slippery surfaces using ceramic tiles and glycerine.

Why EN ISO 20345:2022 Matters

Compliance with EN ISO 20345:2022 is more than just meeting legal requirements- it's about ensuring the safety and well-being of workers in various environments. This standard provides a clear framework for manufacturers and employers, defining the minimum safety requirements that must be met to protect workers from foot injuries. Each marking code in the standard represents a specific set of features that address risks such as impact, penetration, slip resistance, and exposure to extreme temperatures.

By understanding what each marking means, businesses can select footwear that precisely matches the hazards of their specific industry. For example, a construction worker might need S3-rated boots with penetration-resistant midsoles and water resistance, while someone working in the food industry may prioritise anti-slip features. This targeted approach to safety helps in creating a safer working environment, reducing injury rates, and improving overall productivity.

Choosing the Right EN ISO 20345:2022 Footwear

When selecting safety footwear, it's essential to choose a pair that matches the specific risks of your work environment. The marking codes on EN ISO 20345:2022 footwear help you identify the features most relevant to your needs, whether you require basic toe protection, water resistance, or additional features like metatarsal guards and heat-resistant soles.

Explore the ranges of Safety Footwear by WorkWear Experts certified under EN345. Pick the category below.

| Safety Boots | Safety Shoes | Safety Trainers | Waders & Wellingtons |

Your email address cannot be published. Required fields are marked*